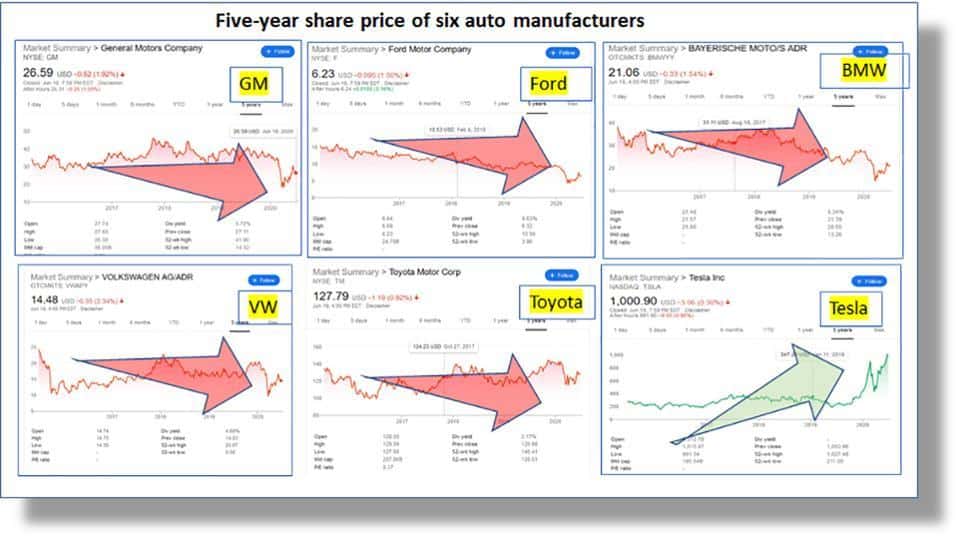

One of the major advantages Tesla has over legacy automakers is its experience in tech. Tesla’s co-founder Ian Wright said back in 2014 that Big Auto’s software tended to resemble “a dog’s breakfast.” Tesla, with its Silicon Valley roots, designed its vehicles from the start with a unified system architecture. “That’s the sort of thing that Tesla gets right in their sleep, and the big guys really struggle with,” Wright said.

Half a decade later, they’re still struggling, as evidenced by VW’s snafu tech with its new ID.3 EV. There are however some deeper lessons to learn from the mindset of Tesla’s software.

Steve Denning is an authority on Agile management, a methodology that prioritizes responding to the needs of the customers and embracing change. He argues in a recent Forbes article that developers of hardware need to embrace Agile principles in order to keep pace with the innovation.

The Agile Manifesto, founded in 2001 by seventeen software developers, promotes four core values: individual relationships with processes and tools; working software rather than thorough documentation; collaborating with clients; and adapting to change rather than following a strategy. For Denning, Agility’s primary concept is “an obsession with the customer’s needs.” He argues that “innovation begins from, and is driven by, the customer’s changing needs.”

This is reminiscent of the famous line from Steve Jobs: “Start with the customer experience and work backwards to the technology,” a principle which Tesla follows with great success. But what does the dichotomy between hardware and software have to do with that?

Many have pointed to the obvious fact that atoms are more difficult to manipulate than ones and zeroes, and have cited this as the reason why innovation tends to occur much slower in the physical realm. If you outline comparisons between the internet boom of the late 1990s and the current transition to electric vehicles. The latter plays out much more slowly, and it’s tempting to assume that this is only because the physical realm of building automobiles (“metal-bending”) happens. Cars can’t be built in a dorm room in contrast to software.

Denning argues that “the atoms-vs-bytes difference is far from being the whole story. Existing manufacturing processes are also slow because they are designed to be slow.” He presents the example of a car door: engineers can come up with a better design, but if an automaker has invested $100 million in a machine which produces the current door, it is unlikely that the revolutionary new door will soon be put into production. Today, it is possible to make rapid improvements to hardware components at a relatively low cost using 3D printing techniques. Why is that not happening? Denning tells us it is not a hardware problem, but a management problem.

You bought a car from a dealer’s lot during the pre-Tesla days and that was the car you had until you wore it out or sold it. Buyers had expected nothing else from a car. However, consumers who have grown up with computers and smartphones “coming to expect what Tesla already delivers: a capability to improve their cars every month or so after purchase through software updates,” Denning writes.

The development of agile software involves designing products in a modular fashion, continuously innovating and incorporating customer feedback and lessons learned in the development process. Agile developers “never arrive at perfect,” Denning writes. “They keep at it. The improvement journey never ends.”

Elon Musk brought some of that mojo of continuous improvement to the world of hardware. “Tesla [uses] traditional CAD tools such as CATIA, but they also invested in an end-to-end 3D modeling system from which they can view and simulate entire assemblies and automatically print parts,” writes consultant Cliff Berg. “Importantly, the software is fast, even when handling complex assemblies, so that engineers do not have to wait, which encourages a rapid iterative design approach.”

Only SpaceX exhibits a similar continuous iteration cycle. “Instead of spending months or years on design and then carefully building one perfect prototype, they build many, and they test them all in myriad ways,” Berg writes. “They want to get the thing to the test stand, even if it has imperfections. To reduce the cost of making parts whose design is always changing, they use 3D printing. This…allows the design to rapidly evolve.”

Musk’s two main companies, Tesla and SpaceX, exhibit new manufacturing methodology. As Denning writes, “they demonstrate that it is possible to run a hardware company like a software company in an Agile fashion.” Can a legacy automaker (or aerospace firm) make the transition to this modern way of thinking?

As many management gurus have lamented, traditional ways of doing things are embedded deeply in the majors’ corporate cultures, and so are outdated definitions of their products. “Car companies are still thinking of a car as a metal transportation device with a few electronic gadgets attached to it,” Denning says, repeating what Ian Wright said years ago. The truth behind automotive innovation’s slow pace: “It’s a leadership and management problem, not a problem of atoms versus bytes.”

Source: Forbes

Be sure to watch the three part CleanTechnica series showcasing Tesla’s factory.

Want to buy a Tesla Model 3, Model Y, Model S, or Model X? Feel free to use my referral code to get some free Supercharging miles with your purchase: http://ts.la/guanyu3423

You can also get a $100 discount on Tesla Solar with that code. No pressure.