Sandy Munro worked in the automotive industry for decades before starting his consulting firm Munro & Associates. In recent years, the firm has made a name for itself with its unique insights into Tesla’s vehicles. Initially, Munro was extremely critical of Tesla’s shortcomings, but as Tesla has continued to improve over time, he has become an outspoken advocate of Tesla.

Much like the legions of Tesla fans around the world, his advocacy stems not from a paycheck coming from Tesla, but from his ground up knowledge of Tesla’s many products in the automotive space. He bases his statements firmly on the technology, materials, and manufacturing systems Tesla is building and continues to improve upon. In a recent video, Munro shared that Tesla has already made at least 13 unique changes to the infamous Octovalve and opened up about why the pace of innovation at Tesla is such a differentiator.

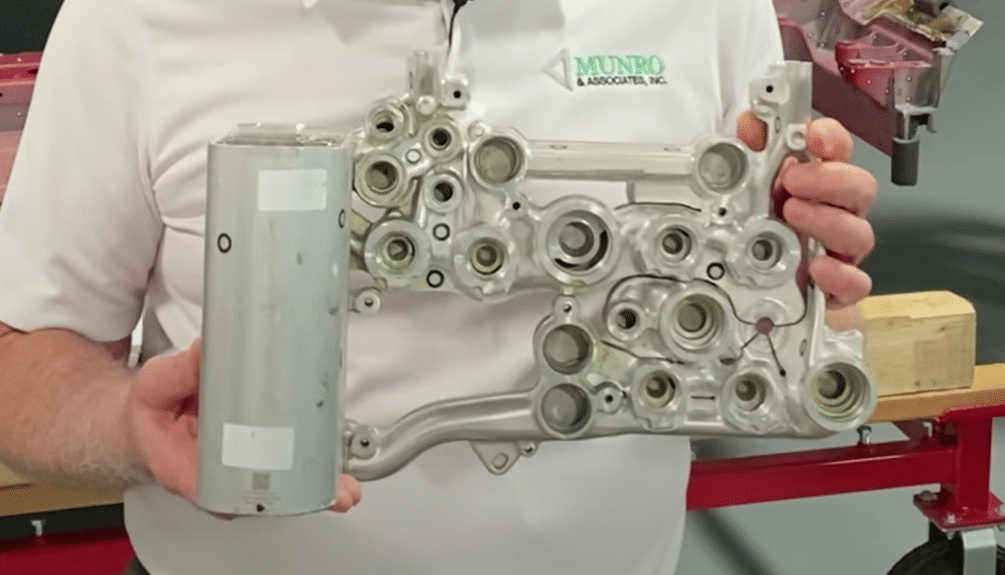

From the time of their initial teardown of the Tesla Model Y to a more recent look at a 1 month old Model Y, Munro and his team found at least 13 unique design changes to the already impressive Octovalve. He shared that from his time working for Ford, it would have been a challenge to get a single design changed moved through to the production vehicle in an full year.

Having first made its debut in the Tesla Model Y, the Octovalve reimagined the thermal management systems for the entire vehicle, merging them into a single, efficient valved system. The result of the efficiencies that came with the Octovalve in the Tesla Model Y translated to a staggering 10% improvement in vehicle range. Read that again. Upgrading the thermal management systems in the Tesla Model Y gave the car 10% more range. That’s staggering. Massive. Game changing.

In addition to the changes to the Octovalve, Munro and his team found at least one other change. On the vehicle they initially tore down, there was no shroud around the compressor, but on the more recent build, Tesla had added a well-designed shroud to the compressor.

Both of these are examples of the unique culture of continuous improvement at Tesla and just how rapidly they are able to identify, validate, and push though changes to the production version of its vehicles. The pace is absolutely staggering and reinforces what we learned on our tour of the Tesla Fremont factory last year. Tesla acts and works like a software company, but in the manufacturing space. Its production lines, hardware, software, solutions, and people are all constantly evolving to build better products today than they did yesterday.

Back then, I wrote:

Tesla is constantly improving. Every day, its seats are getting better than the day before. Each and every day, its software is improving, iterating, evolving. Its welding has been tweaked, its battery chemistry is constantly being refined, battery module designs change, chassis, safety, steering, power output … you name it. That’s why Tesla doesn’t have model years for its vehicles. They are constantly evolving. Each day, or at least each week, Tesla is producing a different car than it was producing a week before.

It’s not just the seats, folks. It’s every single piece of every single product Tesla builds. They are all constantly evolving and improving. It never stops.

Source: Munro & Associates via Reddit

Original Publication by Kyle Field at CleanTechnica.

Want to buy a Tesla Model 3, Model Y, Model S, or Model X? Feel free to use my referral code to get some free Supercharging miles with your purchase: http://ts.la/guanyu3423

You can also get a $100 discount on Tesla Solar with that code. No pressure.