Electrek obtained the first picture of Tesla’s new structural battery pack with a honeycomb architecture that will power its future electric vehicles.

Tesla structural battery pack

At its Battery Day event last year, Tesla not only unveiled its new 4680 battery cell but also a new battery architecture built around the new cell.

Inspired by the aerospace innovation of building airplane wings as fuel tanks instead of building the fuel tanks inside the wings, Tesla decided to build a battery pack that acts as a body structure, linking the front and rear underbody parts.

Currently, Tesla builds battery packs by combining cells into modules, which when put together form a battery pack. That battery pack is installed into the vehicle platform.

The difference with this new concept is that Tesla is not using modules and instead builds the entire battery pack as the structural platform of the vehicle, with the battery cells helping solidifying the platform as one big unit.

Using its expertise in giant casting parts, Tesla can connect a big single-piece rear and front underbody to this structural battery pack.

This new design reduces the number of parts, the total mass of the battery pack, and therefore enables Tesla to improve efficiency and ultimately the range of its electric vehicles.

The structural battery pack is expected to be first used in the Model Y that is going to be built at Gigafactory Berlin and in the new Model S Plaid.

The move is seen as bold in the industry since most electric car makers are trying to protect the battery pack while Tesla is planning to use it as an integral structural part of its electric vehicles.

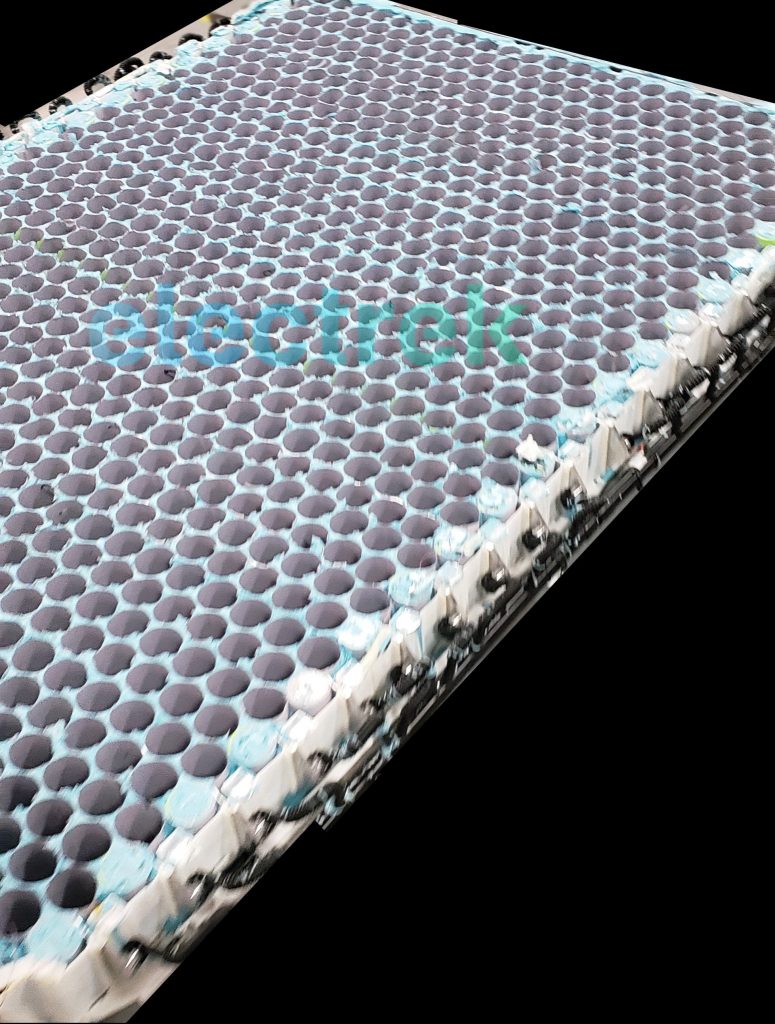

First picture of the Tesla structural battery pack with honeycomb design

Electrek obtained the first picture of one of the very first structural battery packs ever produced by Tesla.

The image shows the battery pack without the new 4680 cells in them – showcasing the honeycomb design of the pack:

Without the cells, we can better appreciate the structural aspects of the honeycomb structure, which is known for its strength while also being lightweight.

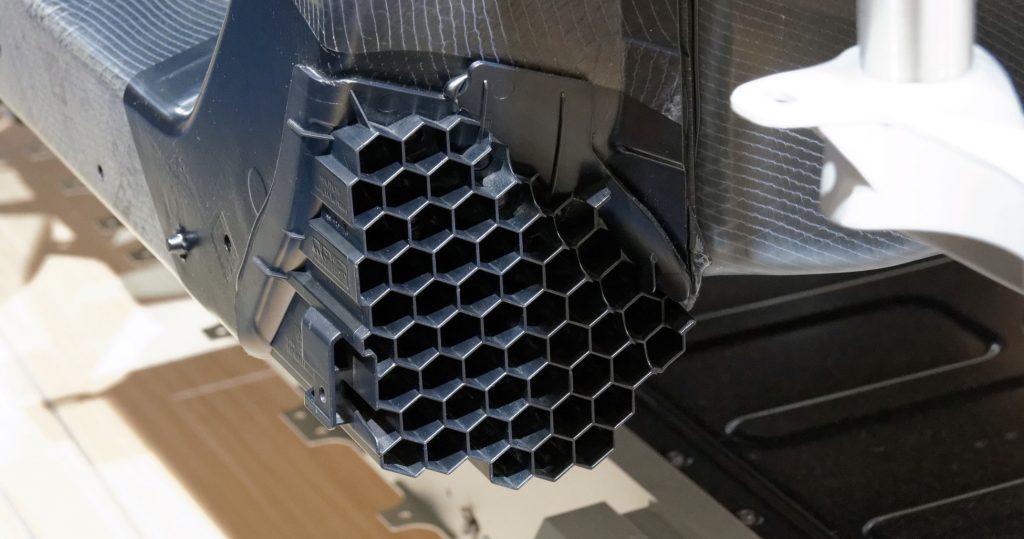

It has already been used in aerospace and in the automotive industry – although not for the same use as Tesla.

The BMW i3 uses a hexagonal honeycomb structure for crash absorption around the vehicle’s battery pack.

On the picture of Tesla’s new battery pack, we can also see that Tesla built the coolant loops on the sides around the pack:

To complete the battery pack, Tesla would drop the 4680 battery cells into the holes and bound them to the pack to contribute to the structural integrity and power the electric vehicles.

Tesla CEO Elon Musk commented on the contribution of the cells to the structure:

Battery pack will be a bonded structure with cells providing shear transfer between steel upper & lower face sheets, eliminating most of the center body parts while providing better torsional rigidity & improved polar moment or inertia. This is a major breakthrough.

Some pointed out that while the benefits of this design are becoming obvious, it also complicates repairs in case of a crash.

However, Musk claims that Tesla designed crash absorption rails that can be cut off and repaired to preserve the packs.

Original Publication by Fred Lambert at Electrek.