Key Takeaways

- Tesla has received a new patent for its “Unboxed Process,” aimed at enhancing manufacturing efficiency and affordability.

- The Unboxed Process shifts from traditional assembly lines to a modular architecture, enabling faster production and lower costs.

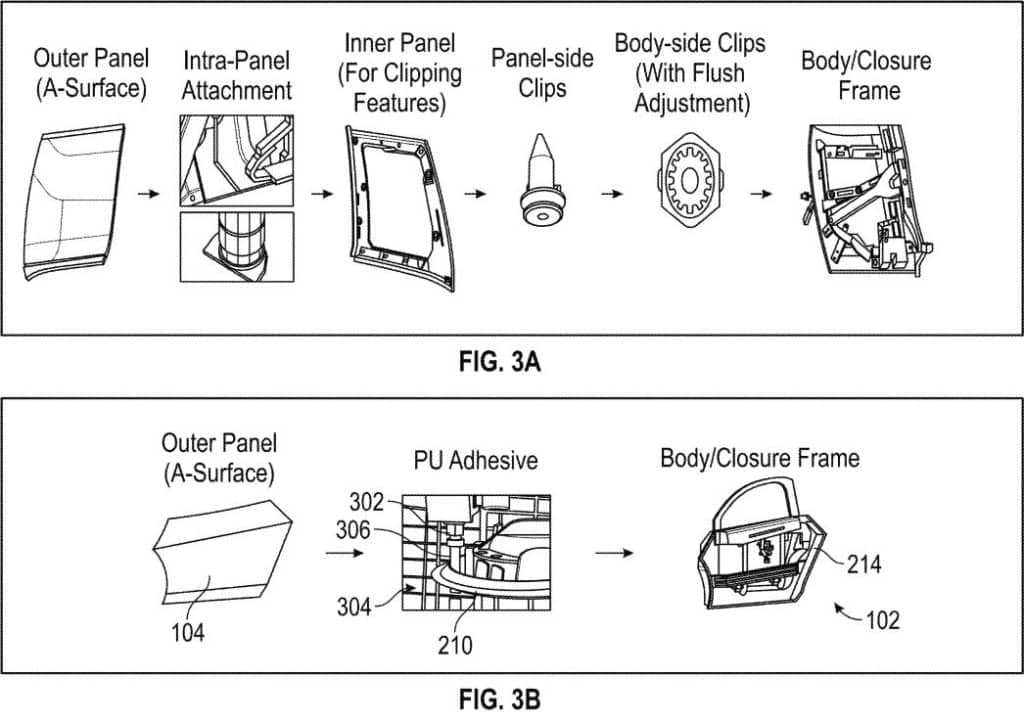

- This new method replaces welding with adhesive bonding, simplifying vehicle assembly by allowing pre-treatment of parts.

- Past technologies like Gigacasting and structural battery integration are integral to this innovative manufacturing approach.

- The goal is to increase vehicle output to meet rising demand for autonomy and Robotaxis while maintaining build quality.

- Traditional manufacturing methods risk compounding errors due to misalignment, which the Unboxed Process seeks to alleviate.

In an era where technology continually pushes boundaries, Tesla remains at the forefront of innovation with its Unboxed Process—an avant-garde approach to car manufacturing. This new patent showcases Tesla’s intent to disrupt traditional assembly lines, making vehicle production faster, more efficient, and ultimately more affordable for consumers.

The Essence of the Unboxed Process

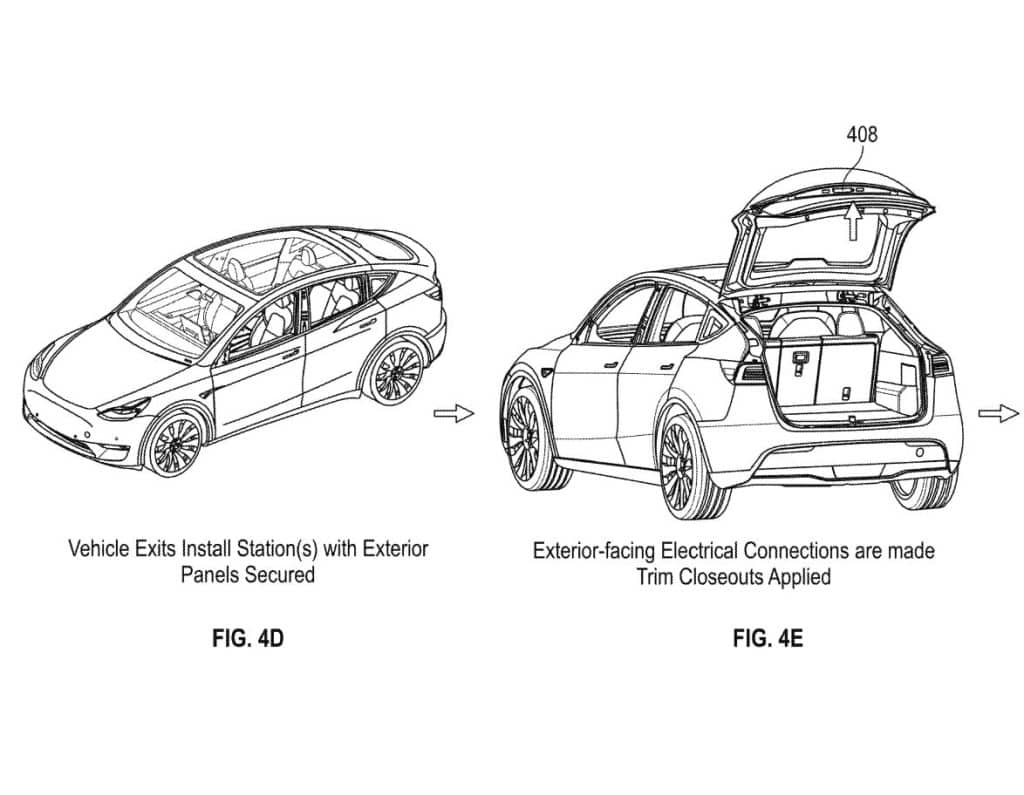

Tesla’s recently patented Unboxed Process represents a significant shift in automotive manufacturing. Traditionally, cars are built using linear assembly lines, which rely heavily on welding stamped panels and applying coatings during full vehicle assembly. The Unboxed Process, however, introduces a modular architecture. This revolutionary system enables vehicles to be constructed in sections, which are then joined together in the final assembly phase.

Key Advantages:

- Efficiency and Speed: By allowing pre-painting and coating treatments, this method accelerates the production process.

- Cost Reduction: The modular system reduces the complexity and cost associated with traditional assembly lines.

- Scalability: As Tesla gears towards mass-market models, this process facilitates scalable manufacturing, essential for meeting growing demands.

Innovative Techniques in Tesla’s Manufacturing Arsenal

Tesla’s Unboxed Process is not just a standalone innovation; it encompasses other pioneering techniques that have previously redefined automotive manufacturing.

- Gigacasting: This technology allows large single pieces of a vehicle’s body to be cast in one go, reducing the number of components and assembly time.

- Structural Battery Integration: By embedding batteries into the vehicle structure, Tesla increases rigidity while optimizing space and weight.

These cutting-edge advancements contribute to the overall efficiency and sustainability that are central to the Unboxed Process.

Replacing Welding with Adhesive Bonding

One of the most transformative aspects of the Unboxed Process is the shift from traditional welding to adhesive bonding:

- Precision and Flexibility: Adhesive allows for precision alignment, compensating for any substructure irregularities.

- Improved Quality Control: The adhesive system supports tacking operations during curing, eliminating the potential for misalignment and ensuring consistent quality.

Addressing the Market’s Evolving Demands

With the emerging trends in autonomous driving and the anticipated rise in demand for Robotaxis, Tesla’s Unboxed Process is a timely innovation:

- Increased Production Volume: By streamlining manufacturing, Tesla can meet the ever-increasing demand for advanced vehicles.

- Affordability: This method promises to deliver quality vehicles at a lower price point, making advanced technology more accessible to a broader audience.

A Leap Toward the Future

Tesla’s Unboxed Process is more than just a manufacturing overhaul; it represents a paradigm shift in how cars are made and what consumers can expect in terms of cost, efficiency, and sustainable innovation. As Tesla continues to push boundaries, the Unboxed Process positions the company to lead the industry into a new era of automotive production.