Key Points

- 💡 Former Northvolt and Tesla workers have founded a new company called Peak Energy.

- 🔋 Peak Energy aims to mass-produce large-scale battery storage systems for renewable energy sources like wind and solar.

- 🧪 The company plans to use lower-cost sodium-ion technology for their batteries instead of lithium-ion batteries.

- 🚀 Peak Energy aims to partner with a technology company specializing in battery tech to help scale its products.

- 🏭 The company intends to produce individual sodium-ion battery cells that can be combined into larger modules for deployment at solar or wind farms.

- 💡 With 100 blocks, their battery system could power as many as 62,500 homes for up to four hours.

- 💰 Peak Energy hopes to offer battery systems at a lower cost compared to Tesla’s Megapacks.

- 💼 The company has announced a $10 million funding round led by former Tesla executive Greg Reichow.

- 🌿 The demand for mass-scale battery storage is expected to grow as more sectors shift toward renewable energy sources.

- 📈 Peak Energy plans to produce “double digit gigawatt” amounts of battery cells by 2030 and build large battery factories with significant investment.

Transitioning to renewable energy requires a multi-faceted approach, and power storage from sources such as solar and wind energy will play an increasingly important role in that playbook in the future. To tackle this problem, former Northvolt and Tesla workers have joined forces to focus on the scalability of battery production with the new company Peak Energy.

Peak Energy aims to mass-produce giant battery storage systems for renewable sources such as wind and solar (via CNBC). CEO and Founder Landon Mossburg formerly worked at Tesla and went on to work as an executive at Northvolt before founding Peak Energy earlier this year.

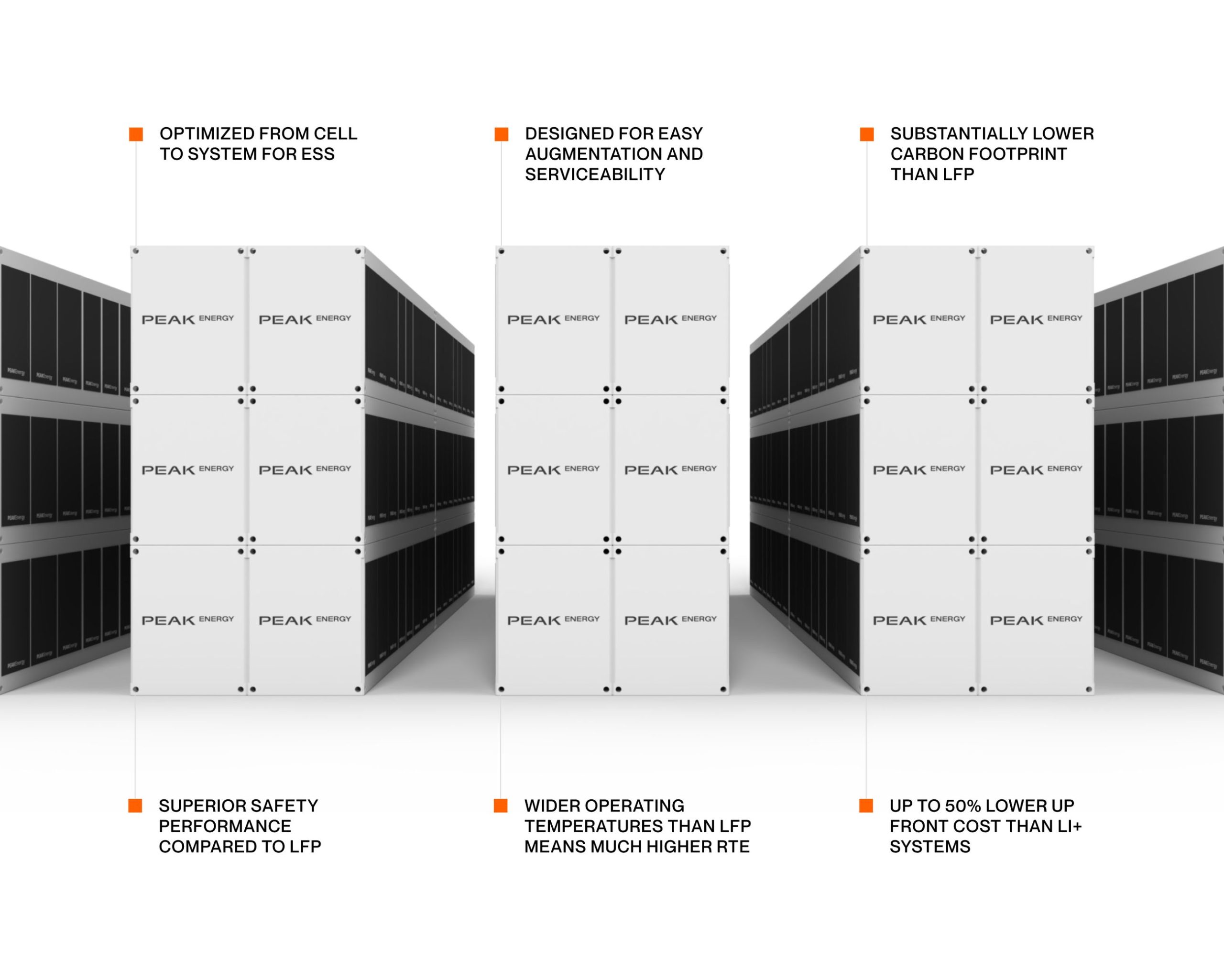

The company plans to scale a more affordable battery chemistry than the lithium-ion batteries used in Tesla’s Megapacks, instead hoping to produce large-scale battery systems with lower-density, lower-cost sodium-ion technology.

Since the company plans to mass-scale an existing product, Peak Energy President and COO Cameron Dales notes that they don’t consider the company a startup, although it only started in June. Interestingly, Peak Energy is looking to partner with a technology company specializing in battery tech, but specifically one that doesn’t yet have the ability to scale its products.

“A normal Silicon Valley startup is 10 years in the lab, come up with a better mousetrap and go to market. We’re completely the opposite,” Dales told CNBC in an interview.

The company plans to make individual sodium-ion battery cells, roughly the size of a loaf of bread, according to Dales. These cells will then be used together to make larger modules about the size of a filing cabinet. These filing cabinet modules could be deployed at solar or wind farms at volumes of 50-100 per order.

With 100 blocks, Mossburg explains, the battery system is expected to be able to power as many as 62,500 homes for up to four hours.

He also thinks that the company’s battery systems could cost around half the cost of a Tesla Megapack’s $1.3 million before installation, though it’s still too early for the company to have a price on its products.

“In the battery market it turns out the rarest commodity is not the technology — there are many excellent ideas out there at academic labs and startups — but rather the ability to scale to manufacturing,” Mossburg said. “The difficulty of manufacturing scale up is one of the reasons you see so many ‘breakthrough battery technology’ announcements but very very few companies who actually reach market.”

The company has also announced a $10 million funding round led by Eclipse Ventures’ Greg Reichow, a former Tesla executive who was in charge of battery, motor and electronics manufacturing before going on to lead global manufacturing. Crucially, Dales points out to CNBC that Reichow also led the development of Tesla’s Giga Nevada battery factory with partner Panasonic, which he considers the first mass-scale battery factory in the world.

TDK Ventures, owned by Japanese multinational electronics manufacturer TDK, will also join the funding round.

“The number one issue we face as it relates to expanding renewable energy sources is storage,” Reichow said. “This problem must be solved, but the existing approaches using lithium-ion and other technologies are not yet at a price point that enables the kind of scaling that society needs across sectors.”

The U.S. Energy Information Administration forecasts battery storage capacity to increase from just 9 gigawatts last year to as much as 49 GW by 2030 before jumping to 247 GW in 2050. This projection shows demand for mass-scale battery storage will continue to grow, especially as transportation and other sectors shift toward renewable energy sources.

Peak Energy currently hopes to produce “double digit gigawatt” amounts of battery cells by 2030, set to be used for its own battery systems and other applications. According to Mossburg, building a battery factory will take between $50 million and $100 million per GW. He also says a 30 GW factory would have between 2,000 and 3,000 workers, requiring a 1-2 million square-foot space.

Mossburg has experience scaling battery production at Northvolt, founded by former Tesla Global Head of Sourcing and Supply Chain Peter Carlsson, who worked for the automaker from 2011-2015. By the time Mossburg left Northvolt, the company had grown to employ 4,000 people from just 300 only 18 months prior.

″We’re running a playbook which I and the rest of the executive team initially demonstrated and deployed at Northvolt,” Mossburg said.