Tesla was in a very different position back in 2018. The firm was struggling to release the Model 3, and it was behind on Elon Musk’s ambitious self-imposed vehicle development goals. The Fremont Factory assembly lines were not producing enough Model 3s, and it looked like the company was poised to fail. Critics and shorts circled Tesla like sharks smelling blood in the sea. Yet a peculiar thing happened, and things were never the same afterwards.

Throwing convention out the window on the Fremont Factory grounds, Tesla built another Model 3 line inside a massive sprung structure, which CEO Elon Musk affectionately called a “tent.” The device, dubbed as GA4, was ridiculed to the highest degree, used by critics as a joke, and outright disregarded by skeptics. What was almost unknown at the time, however, was that Tesla may have potentially stumbled with its sprung structure-based line into something special. Tesla appears to have developed a strong Gigafactory formula effectively by building a simple, straight, Model 3 line within a “tent.”

In the early days of the Model S, the spring structure-based Model 3 line was the brainchild of Automotive President Jerome Guillen, commonly regarded as Elon Musk’s “problem solver.” A relatively simple process followed the “tent”-based line, with vehicles being assembled gradually the further they went into the tent. Even the loading bays of GA4 were placed on the sides of the system, enabling Tesla to effectively take deliveries into the line. Not long after the “tent” was constructed, Musk was enthusiastic about the sprung structure on Twitter, mentioning that the automobiles manufactured on the site had “slightly higher quality” than cars produced elsewhere.

These modest but innovative beginnings seem to have been the foundation of the Gigafactory formula of Tesla, one used in Giga Shanghai and Giga Berlin, and with Gigafactory Texas seemingly further enhanced. This can be seen in the design and procedures adopted by Tesla so far in its plants in Shanghai and Berlin, both of which evoke the picture of a scaled-up, refined and optimized version of the Fremont “tent.”

Tesla critics usually ignore the fact that the Fremont Factory at its heart is a legacy car facility. It is an enormous facility, and is impressive in its own right, but it is not a site explicitly built to manufacture all-electric vehicles. Thus, for the early days of Model S, Model X, and Model 3, Tesla was basically designing a system that produces EVs at scale using a facility originally designed to produce automobiles fitted with an internal combustion engine.

Tesla has, of course, made several changes to make the Fremont Factory one of the market’s most advanced electric vehicle facilities. However, in Gigafactory Shanghai, arguably the first EV factory that the company developed using its GA4 formula, with its simple production lines at its side to its numerous loading bays, it is hard not to be impressed with Tesla’s fast production ramp and versatility. This idea seems to have been passed to Gigafactory Berlin, which is expected to scale up its activities at a pace that also rivals Giga Shanghai.

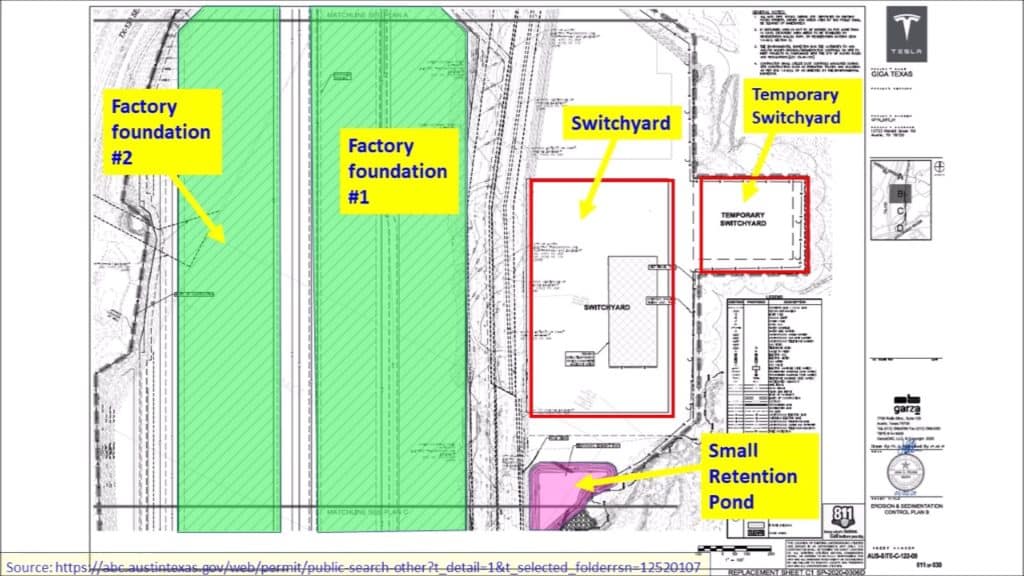

Ultimately, it seems that, at least for its electric vehicle factories, GA4 was Tesla’s “eureka” moment of sorts. Tesla was able to build monster factories such as Giga Shanghai by scaling up and refining the sprung structure-based model, and also Gigafactory Berlin later this year. This is not all, however, as Tesla appears to be implementing an improved Gigafactory Texas architecture, with its three main buildings designed parallel to each other. Little is known about the reasons behind Giga Texas’ construction, but there is little doubt that when completed, the massive facility will nevertheless be quite impressive.

Elon Musk talked about Tesla’s “Alien Dreadnought” factories prior to the “production hell” of Model 3, which are supposed to be so automated and advanced that they would mimic alien facilities featured in sci-fi fiction. Tesla seems to have shelved this concept following the challenges of the Model 3 in its initial production ramp. However, with an existing Gigafactory formula of sorts in its arsenal, and combined with inventions such as the Model Y megacasts, the Elon Musk dreadnoughts might not be too far into the future at all.

Ready to join Tesla’s Mission to accelerate the world’s transition to sustainable energy? Feel free to use my referral code to get some free Supercharging miles with your purchase: http://ts.la/guanyu3423

You can also get a $100 discount on Tesla Solar with that code.