Key Takeaways

- Tesla’s in-house 4680 battery cells have achieved the lowest cost per kWh production.

- The Texas manufacturing team has scaled production to become more cost-effective than external suppliers.

- CEO Elon Musk highlighted the achievement, emphasizing its significance given Tesla’s diverse business focus.

- Michael Guilfoy, Tesla’s Giga Texas Director, praised the team’s hard work and projected future milestones in 2025.

- Despite partnerships with companies like Panasonic and LG, Tesla is increasing its internal 4680 battery cell production capabilities.

- In September, Tesla surpassed the production of 100 million 4680 battery cells, marking a rapid increase.

Tesla has achieved an extraordinary milestone in its battery production journey, marking a significant leap in both technological innovation and cost-efficiency. In recent months, Tesla’s in-house 4680 battery cells have hit a remarkable milestone: becoming the lowest-cost battery cell in terms of kWh production. This achievement underscores Tesla’s capacity for innovation, proving that the electric vehicle behemoth can outpace traditional suppliers in cost-effectiveness, even as it balances a diverse array of business objectives.

A Leap in Cost Efficiency

Tesla’s in-house 4680 battery cells, manufactured at their Texas facility, have achieved the lowest cost per kilowatt-hour production, underlining the company’s relentless pursuit of innovation and efficiency. This milestone is significant, especially given that many of Tesla’s competitors and suppliers focus solely on battery cell manufacturing. Tesla, on the other hand, operates across various sectors, yet it managed to achieve a lower cost-per-kWh battery production.

The Role of the Texas Manufacturing Team

The Texas manufacturing team has been pivotal in this achievement. They have scaled up production to such an extent that Tesla’s in-house capability is now more cost-effective than external suppliers. During Tesla’s first-quarter all-hands-on-deck meeting, CEO Elon Musk lauded the team’s success, emphasizing the broader implications for Tesla’s diverse business ventures.

Leadership and Future Projections

Michael Guilfoy, Tesla’s Giga Texas Director of Cell Manufacturing, has been vocal in praising the team’s hard work and dedication. He projects even more significant milestones in 2025 with the full ramping of dry battery electrode manufacturing, which will deliver even more cost efficiencies. It’s a testament to the team’s grit and passion, reflecting Tesla’s mission to accelerate the global transition to sustainable energy.

A Surge in Production Capacity

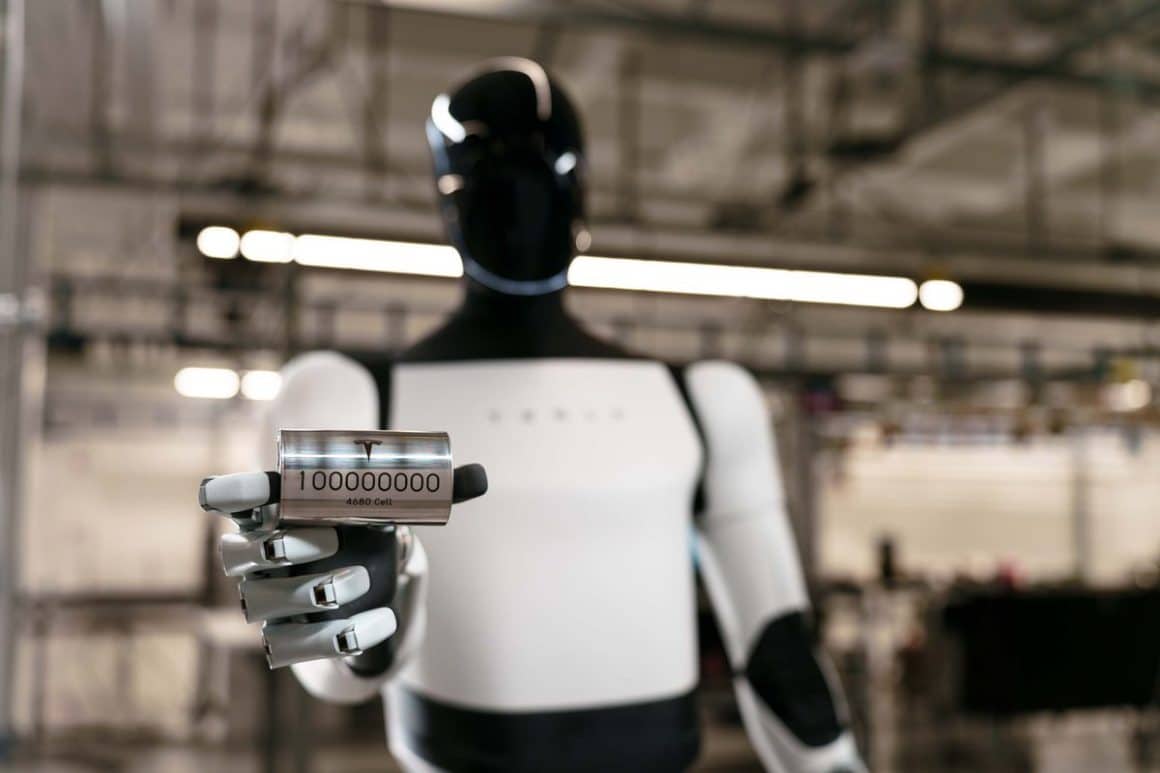

Despite collaborations with battery giants like Panasonic and LG Energy Solution, Tesla continues to bolster its internal 4680 battery production. This dual strategy allows Tesla to maintain flexibility and control over its supply chain while still benefiting from strategic partnerships. In September, Tesla reached a milestone of 100 million 4680 battery cells produced, demonstrating rapid growth and production scale.

Tesla’s Vision for the Future

The 4680 battery cell is not just a technical achievement; it’s a cornerstone of Tesla’s vision for the future. The implications are extensive, from reducing vehicle costs to enhancing vehicle performance and promoting sustainability. As Tesla continues to innovate, the world watches with bated breath to see what advancements will follow.

Tesla’s Strategy Versus Other Suppliers

Tesla’s in-house battery production capability poses an intriguing challenge to traditional suppliers. By achieving lower costs through internal innovation, Tesla sets a new benchmark for the industry. This internal capacity allows Tesla to deftly navigate market fluctuations and technological challenges, providing them with a competitive edge over other EV manufacturers.

Tesla’s 4680 battery cell milestone is a critical development in the evolution of electric vehicles. It represents more than just a cost reduction; it’s about redefining what’s possible in battery technology. As Tesla continues to push the boundaries of what’s possible, the world can expect further groundbreaking innovations from this industry leader.