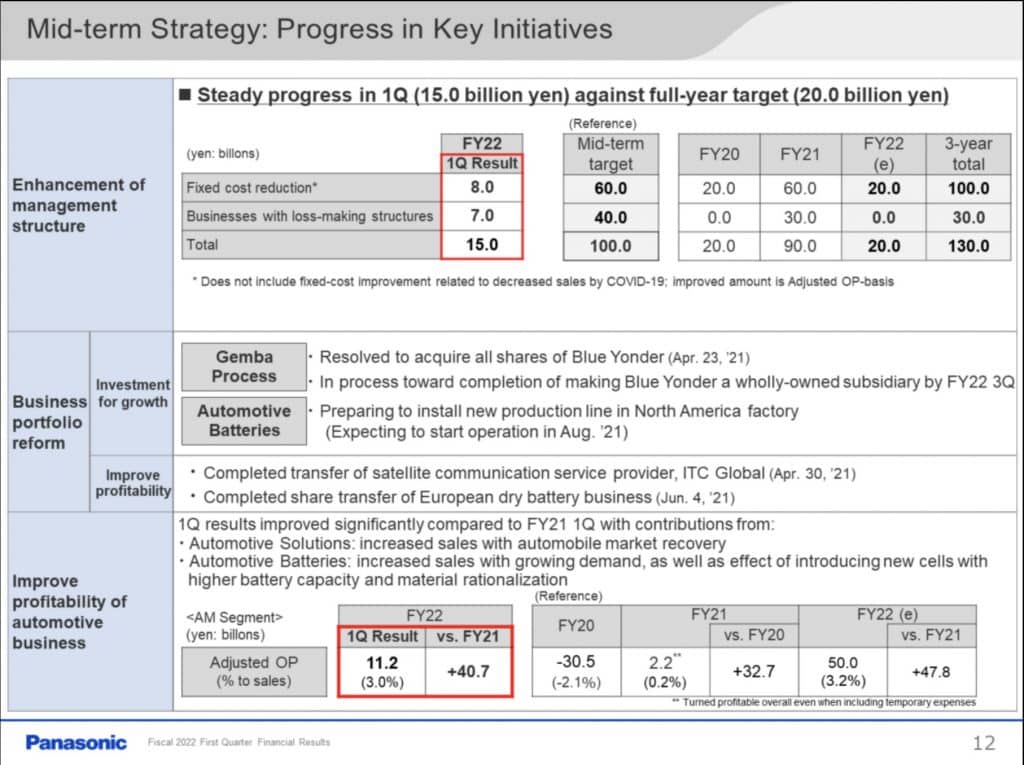

Panasonic is preparing to install a new production line in Tesla’s Gigafactory Nevada, according to its Fiscal 2022 First Quarter Financial Results report. The company expects the new production line for automotive batteries to start operations by August 2021.

Panasonic reported that its automotive sales increased by 77% to ¥373.7 billion ($3.42 billion), mainly due to the rise in Automotive Solution sales caused by a recovering automobile market. The company reported a growing demand for automotive batteries, too.

Panasonic also mentioned the introduction of new cells with higher battery capacity and rationalization. Given Panasonic’s history with Tesla, it is likely referring to Gigafactory Nevada. The batteries with higher capacity are probably the 2170 cells used in the Model 3 and Model Y, two high-volume vehicles that form the backbone of Tesla’s sales today.

Panasonic has previously noted that it is looking to expand its production capacity in Gigafactory Nevada in Fiscal Year 2022. According to the Japanese tech conglomerate, it would be looking to reach a capacity of 38-39 GWh once its new production line is installed in its North American site.

Apart from expanding Gigafactory Nevada’s capacity, Panasonic has also made progress in developing a prototype line for 4680 cells, the same form factor that Tesla is developing in its Kato Road facility. The 4680 cells are a pivotal part of Tesla’s plans for the future. At the second-quarter earnings call, Elon Musk mentioned that Tesla plans to produce Model Ys in Giga Berlin and Giga Texas with a structural battery pack equipped with its 4680 battery cell.

“We’re also aiming to do a structural pack with 4680 cells, which is a mass reduction and a cost reduction, but we’re not counting on that as the only way to make things work. We have some backup plan with a non-structural pack and 2170s essentially,” Elon Musk stated at the last earnings call, which he attended while being in Giga Texas.

Andrew Baglino, Tesla Senior Vice President of Powertrain and Energy Engineering, noted that Tesla has successfully validated the performance and lifetime durability of the 4680 cells produced in the company’s Kato Road facility. Tesla continues to verify the cells’ reliability as well. He noted that the main challenge Tesla is facing with 4690 cell production is not “a science problem, but an engineering problem.”

“We have a challenge with basically what’s called calendaring, or basically squashing the cathode material to a particular height,” explained Elon Musk.

“So it just goes through these rollers and gets squashed like pizza dough, basically, but very hard pizza dough. It’s denting the calendar rolls. This is not something that happened when the calendar rolls were smaller, but it is happening when the calendar rolls were bigger.”

Panasonic’s Fiscal 2022 First Quarter Results could be accessed below.