Key Takeaways

- Giga Berlin celebrates one year without discharging process wastewater into the municipal sewer system.

- The facility returned 377,000 cubic meters of annual water rights to local authorities.

- Andre Thierig, the plant manager, highlighted the achievement as a testament to Giga Berlin’s commitment to sustainability.

- Jochem Freyer praised Tesla for its positive environmental impact in East Brandenburg.

- The factory’s advanced wastewater treatment systems contribute to making it one of the most eco-friendly vehicle production sites in the region.

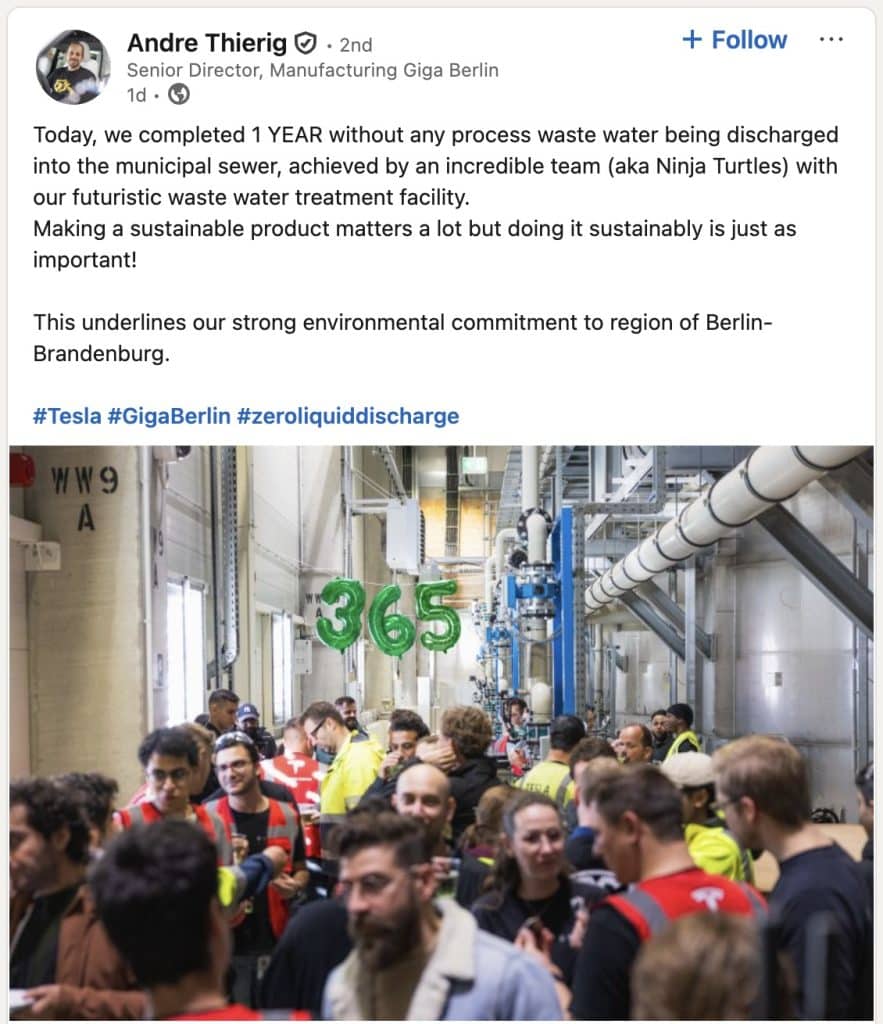

In the ever-evolving world of automotive production, Tesla’s Giga Berlin is a shining example of innovation meeting environmental responsibility. As the factory celebrates a full year without discharging process wastewater into the municipal sewer system, it’s clear that sustainability is not just a buzzword but a deeply ingrained ethos at Tesla.

The Milestone: A Year Without Wastewater Discharge

Tesla’s Giga Berlin has marked an incredible achievement: one entire year without discharging its process wastewater into the municipal sewer system. This feat is a testament to the factory’s advanced waste treatment systems and its overarching commitment to environmental sustainability.

How Did Tesla Achieve This?

- Innovative Wastewater Treatment: At the heart of this achievement lies Giga Berlin’s cutting-edge wastewater treatment system, touted to be on the frontier of modern technology.

- Visionary Leadership: Andre Thierig, Giga Berlin’s Senior Director of Manufacturing, addresses this milestone as a demonstration of the factory’s environmental commitment, underscoring how sustainability is intertwined with Tesla’s production goals.

Returning Water Rights: A Commitment Beyond Compliance

Tesla has returned a staggering 377,000 cubic meters of annual water rights to local authorities. This substantial volume is a direct result of the facility utilizing significantly less water than originally planned, showcasing Tesla’s unparalleled efficiency and foresight.

What Does This Mean for the Community?

- Local Impact: The water saved and returned by Tesla is being redallocated for use by municipalities and other local organizations, providing an economic and ecological boon to the region.

- Official Recognition: Jochem Freyer, Chairman of the Management Board of the Employment Agency Frankfurt (Oder), hailed Tesla’s decision as a transformative and forward-thinking move benefiting East Brandenburg.

Sustainability at Its Core: Why Giga Berlin Leads the Way

Giga Berlin stands as one of the most environmentally friendly vehicle production sites in the region. The plant’s efforts in sustainability extend far beyond wastewater management to encompass a comprehensive approach that includes every aspect of production.

Key Sustainability Practices at Giga Berlin

- Efficient Resource Use: By optimizing energy and material use, Giga Berlin minimizes waste and environmental footprint.

- Renewable Energy Integration: The integration of solar and other renewable energy sources supports Tesla’s goal of carbon neutrality.

Looking Forward: What’s Next for Giga Berlin?

As Giga Berlin continues to innovate, future sustainability goals aim to further decrease the facility’s environmental footprint while increasing efficiency. This vision not only drives Tesla’s internal policies but also sets benchmarks for the automotive industry as a whole.

Future Sustainability Goals

- Continued reduction in overall resource consumption.

- Expansion of renewable energy sources within the facility.

- Development of more sustainable production processes.

Tesla’s Giga Berlin is more than just a factory; it’s a paradigm of what the future of automotive manufacturing could look like when paired with genuine environmental commitment. As the company continues to push the boundaries of innovation, its sustainability efforts remain front and center, proving that progress and responsibility can indeed go hand-in-hand.