Tesla plans to start building battery packs for the upcoming Cybertruck on a new cell manufacturing line in the Fremont factory, people with knowledge of the project told Teslarati.

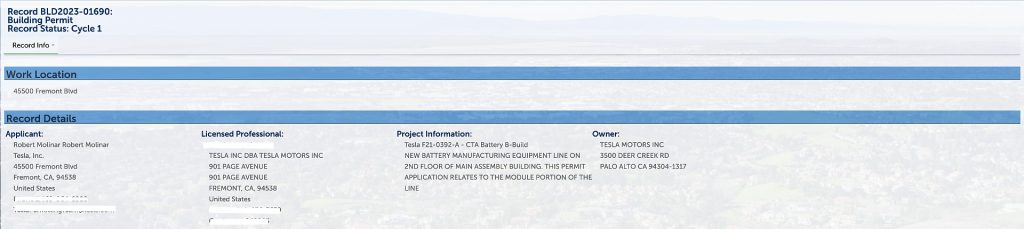

In August, we reported that Tesla had filed to build a new battery manufacturing equipment line on the second floor of the Fremont factory. This filing, which was submitted to the City of Fremont on August 30, relates to the module portion of the line, Tesla said.

Tesla described the project as “CTA Battery B-Build,” the filing shows.

Tesla is ultimately planning to build the Cybertruck in Austin at Gigafactory Texas. However, battery cells and cell pack manufacturing are not yet ready to take off at the new Tesla plant, which is located just outside Austin. Tesla applied to build a battery and cathode manufacturing building at Gigafactory Texas earlier this year, and while the project has been started, it likely will not be ready for the Cybertruck’s projected launch in mid-2023.

With an extensive order log that features over 1 million total reservations, Tesla is preparing for Cybertruck manufacturing by building the battery packs at a plant that is already operational. The Fremont facility, the only Tesla plant manufacturing all four vehicles the company builds, was ultimately chosen for the task of kicking off Cybertruck pack manufacturing, Teslarati confirmed with sources familiar with the matter.

CYBERTRUCK BATTERY PACK MANUFACTURING WILL START IN FREMONT

Sources familiar with the matter told Teslarati the second-floor manufacturing line that Tesla filed to build in August will manufacture the Cybertruck packs. Tesla will take the 4680 battery cells produced at the Kato Road facility or another previously utilized cell design manufactured at Gigafactory Nevada and put them into modules and packs that are manufactured on the new Fremont battery line.

Currently, the line is being completed by construction crews on site, who are making daily progress. Additionally, Tesla engineers are installing automation equipment to produce the Cybertruck battery packs.

Tesla did not immediately respond to our request for comment.

KICKING CYBERTRUCK MODULE PRODUCTION INTO “PLAID MODE”

Tesla is also working hard to kick off Cybertruck pack production as time is extremely limited. Tesla has a series of vehicles, referred to as “carriers,” which transport batteries throughout the factory. The company recently ordered around 300 new carriers for the factory as cell and battery pack manufacturing is set to ramp drastically.

The sources also said the Cybertruck battery pack line is currently being tested with Tesla’s automation equipment. Tesla is working to ramp the line quickly as Cybertruck vehicle manufacturing is planned for next year at Gigafactory Texas.

2023: THE YEAR OF THE TESLA CYBERTRUCK?

Tesla is set to build the Cybertruck at Gigafactory Texas. After unveiling the all-electric pickup in 2019, Tesla has delayed initial production on several occasions due to supply chain issues and other challenges.

“In 2022, supply chain will continue to be the fundamental limiter of output across all factories,” Musk said during Tesla’s Q4 and 2021 Full Year Earnings Call in January. So the chip shortage, while better than last year, is still an issue. And, yeah, so that’s — there are multiple supply chain challenges.”

Musk went on to say that the challenges would delay the launch of any new products in 2022. “We will, however, do a lot of engineering and tooling, what not to create those vehicles: Cybertruck, Semi, Roadster, Optimus, and be ready to bring those to production hopefully next year. That is most likely.”

Although Tesla is planning to begin deliveries of the Semi on December 1, all other projects have been effectively delayed until next year, but preparation to launch those projects is evidently a priority within the factories.

4680 CELLS ARE NOT CONSTRAINED BUT ARE THEY GOING INTO THE CYBERTRUCK?

Tesla’s Vice President of Powertrain Drew Baglino detailed earlier this year that the company was not constrained in terms of 4680 battery cell availability.

“So throughout 2021, we focused on growing cell supply alongside our in-house 4680 effort to provide us flexibility and insurance as we attempt to grow as fast as possible,” Baglino said on the Q4 and Full Year 2021 Earnings Call in January. “4680 cells are not a constraint to our 2022 volume plans based on the information we have.”

What Baglino said next on the call likely indicates what Tesla was preparing for with the Cybertruck: pack manufacturing at Fremont, shipping the packs to Texas, and then installing them into vehicles:

“But we are making meaningful progress of the ramp curve in Kato. We’re building 4680 structural packs every day, which are being assembled into vehicles in Texas. I was driving one yesterday and the day before. And we believe our first 4680 vehicles will be delivered this quarter.”

The Kato Road facility has supported Tesla’s 4680 cell needs thus far. The 4680 packs were installed on some Gigafactory Texas-built Model Ys, and were reviewed by Munro Live earlier this year. Fremont will likely support Cybertruck pack manufacturing for some time, utilizing cells from Kato Road and from suppliers like Panasonic when they ultimately being manufacturing the battery for Tesla.

As Cybertruck manufacturing ramps up into late 2023, 2024, and beyond, packs will then be at Fremont and Gigafactory Texas, which would likely entirely support Cybertruck production.