Siemens and Tesla are both working on ways to reduce the time it takes to install fast chargers by using pre-fabricated systems. Not only do pre-fab techniques reduce construction times, they lower costs as well. The VersiCharge XL concept — developed in partnership with Nexii Building Solutions — builds on proven power distribution technologies similar to those used in data centers and industrial plants and enables new or existing parking lots and building structures to be electrified quickly and efficiently, according to Electrive.

Thanks to its scalability, this solution can be installed outdoors and can be equipped with Level 2 or Level 3 fast chargers, according to the needs of individual customers. It also permits a simple way to expand the installation as demands change and it simplifies maintenance.

A VersiCharge XL prototype has already been completed at the Siemens research and development center for electrical products and e-mobility solutions in Peachtree Corners, Georgia. Installation took just 3 days, the company says. The building material — manufactured by Nexii in the US — has properties comparable to concrete, but with a much lower carbon footprint

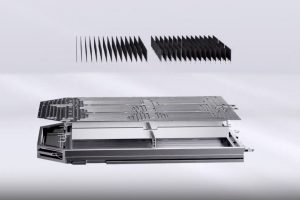

The prototype is the industry’s first EV charging system to house all the necessary components to power EV chargers above ground in a closed, low carbon structure. This eliminates costly and time consuming construction work, while reducing construction waste and environmental pollution on site.

“The enormous growth in electromobility requires the simple and rapid expansion of a reliable and sustainable charging infrastructure,” says Markus Mildner, CEO of eMobility at Siemens Smart Infrastructure. The concept shows how Siemens and its partners are working on innovative ideas “to support this growth in the US market.”

Tesla Supercharger Completed In 8 Days

Tesla also is using pre-fabrication techniques to get new Supercharger plazas installed more quickly. The latest 12-charger plaza in Brooksville, Florida, was completed in just 8 days, thanks to the use of pre-assembled chargers that came loaded on a flatbed truck to the job site.

Tesla expects to increase the size of its Supercharger network by 31% in 2022, from 3,382 stations and more than 30,000 stalls to an additional 1,047 stations and 10,000 more stalls. About 38% of the Supercharger network has V3 chargers that deliver up to 250 kW of power, according to Inside EVs. Tesla is in the process of increasing the power of its V3 chargers to 324 kW and is working on V4 equipment that will exceed 350 kW.

As more EVs take to the road and charging speeds increase, pre-manufacturing charging infrastructure will save lots of time and money and help to move the EV revolution forward more quickly.