Redwood Materials announced today it would build its next Battery Materials Campus in Charleston, South Carolina.

Redwood, which has partnerships with companies like Toyota, Volvo, Ford, Tesla, Panasonic, and Envision AESC, recycles, refines, and remanufactures EV battery anode and cathode materials to reduce CO2 emissions associated with the production of cells. Former Tesla Chief Technical Officer J.B. Straubel founded the company.

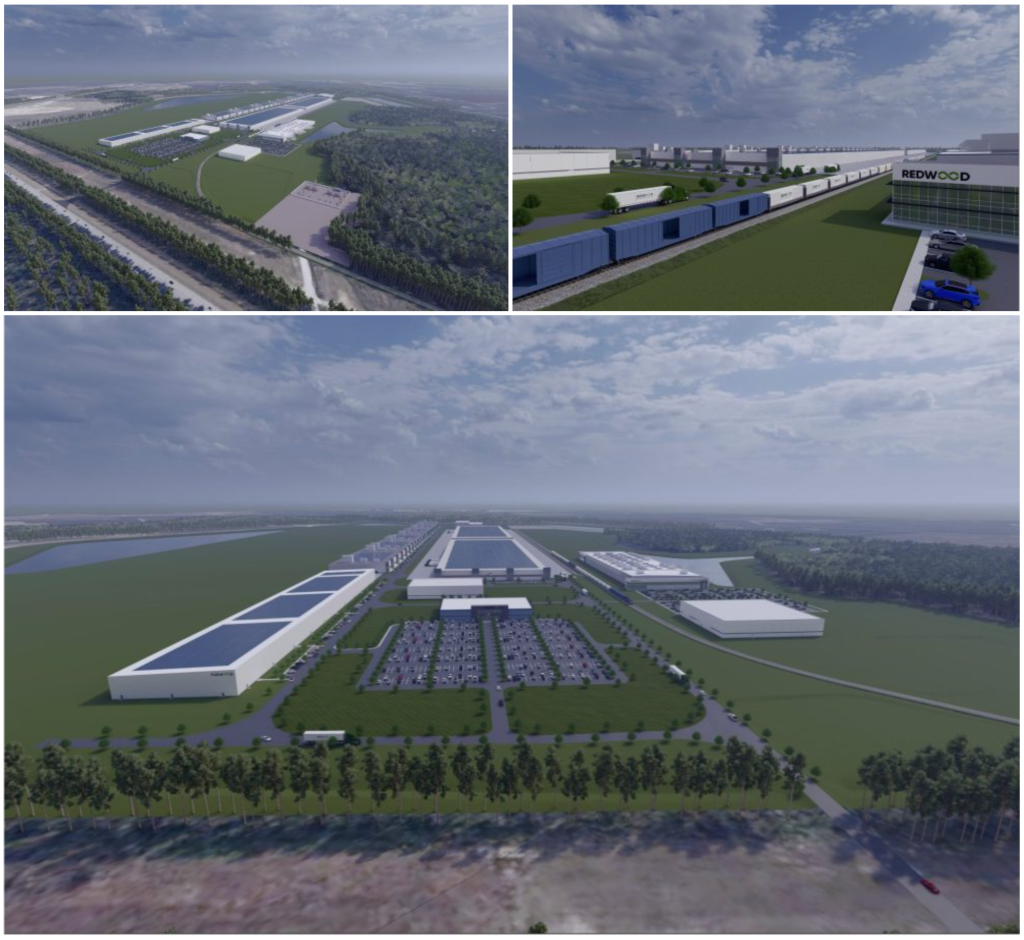

Redwood said its next facility’s placement at Camp Hall in Berkeley County, South Carolina, would help create more than 1,500 jobs in the next decade as the company plans to invest $3.5 billion. Charleston is located in the heart of the ‘Battery Belt,’ where more than 600 acres will be utilized for recycling, refining, and remanufacturing electric vehicle battery components.

South Carolina is one of the most ideal locations for Redwood’s next remanufacturing plant, as it is home to more than 500 automotive companies and over 72,000 autoworkers. Along with the city’s reputation as one of the best places in the world to live, work, and visit, the Port of Charleston’s ideal and nearby location will allow Redwood to import raw materials that can be refined on-site. The facility will also be served by rail access for efficient logistics.

“When paired with the benefits of the recent Inflation Reduction Act, this strategic location also allows us the opportunity to invest more heavily at home while potentially exporting components in the future, allowing the U.S. to become a global leader in this manufacturing capability,” Redwood said.

With excessive demand for EVs and a need for more batteries and battery materials to keep up with consumer needs, Redwood’s goal is to localize the production of critical battery components to keep costs and emissions down while not having to rely on foreign entities or geopolitical conditions to keep prices and supplies stable.

Redwood will break ground in Charleston in Q1 2023 and will have the first recycling processes up and running by year-end. The facility will be operated with 100 percent electric and will use no fossil fuels or natural gas in any of its processes. In fact, Redwood will not pull a gas line to the site to support this.

Redwood first visited South Carolina a year ago to scope out sites for its next Battery Materials Campus. Straubel is more than convinced the state will offer precisely what the company needs in its efforts to expand battery repurposing:

“South Carolina’s commitment to creating a secure energy future and a competitive landscape for electric vehicle manufacturing, supported by a world-class workforce, fast and efficient logistics, zero-carbon electricity and a phenomenal site made it a smart decision for Redwood to invest here. Redwood’s South Carolina Battery Materials Campus will recycle, refine and remanufacture anode and cathode components allowing us to support our current and future customers in the heart of America’s battery belt. We’re ready to support this region and U.S. electrification by driving down battery costs, emissions, and reducing reliance on foreign supply chains.”