Mercedes-Benz officially opened its new €200 million Electric Software Hub at the Mercedes Technology Center (MTC) in Sindelfingen, a city in South Germany. The Hub, which aims to accelerate the German automaker’s transition to electrification, will combine numerous software, hardware, system integration, and testing functions under one roof, intensifying Mercedes-Benz’s approach to cross-functional collaboration.

The Electric Software Hub aims to help Mercedes adopt its goals for a fully-electric future at an accelerated pace. With goals to develop only electric architectures from 2025 and beyond, the company is taking a holistic approach in terms of vehicle software, ranging from basic research to complex coding. The factory is expected to add around 1,000 jobs related to software developers at the Sindelfingen plant alone, with 2,000 additional employment opportunities being added to the global R&D network.

“The Electric Software Hub is an epicenter of our research and development and at the same time closely networked with the worldwide production sites,” Markus Schäfer, Member of the Board of Management of Mercedes-Benz Group AG, Chief Technology Officer responsible for Development and Procurement, said. This is where key aspects of the future of Mercedes-Benz become reality – especially our own MB.OS operating system. Cars are among the most complex products in general. The hardware and software are decoupled and must work together perfectly. We ensure this in the Electric Software Hub. It is our software integration factory.”

The new MTC in Sindelfingen has 753,474 square feet of space over eight floors. “The inside of the Electric Software Hub reflects the entire electrics/electronics integration process of vehicle development. The employees ensure that all hardware and software components created in research and development work perfectly and interact seamlessly. From top to bottom – from code to product – software and hardware enter further and further into the vehicle until they are integrated into vehicle prototypes in the lower spaces,” Mercedes said regarding the new facility.

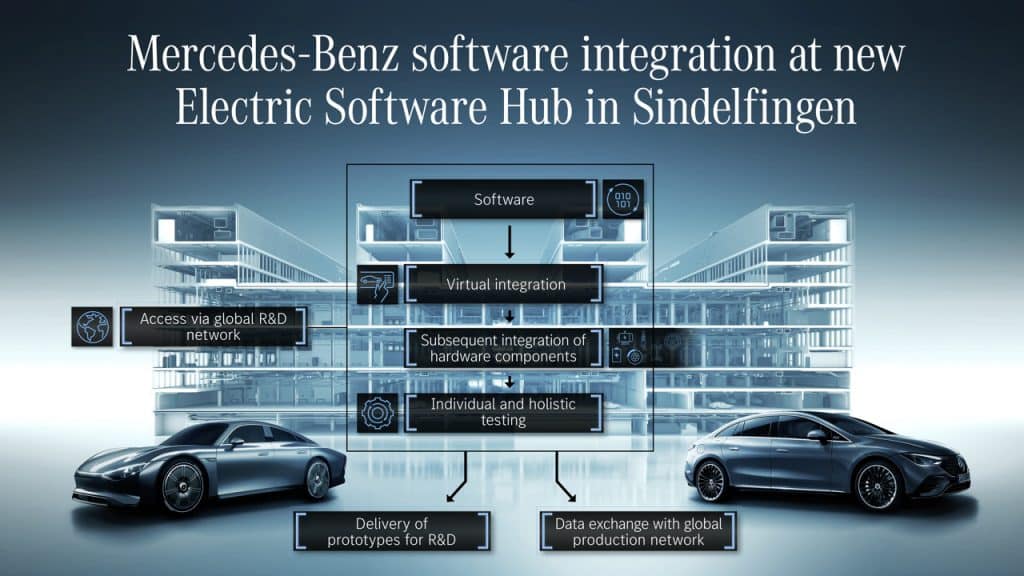

Chief Software Officer Magnus Östberg said, “Through the Electric Software Hub, we are able to quickly and safely integrate new software components into a production vehicle in an interactive environment. Our global digital hubs develop these independently of location and around the clock. First, we link the software components together virtually. We then test and optimize them for the highest customer demands. Our developers can access the flexible and networked test benches from all over the world and test their software on prototypes of the control units. This is then tested with the rest of the hardware in the vehicle and finally checked for suitability for series production and everyday use. These endurance tests include exposure to heat, cold, and rain. In this process, we work efficiently together in international teams physically as well as remotely in one building. This makes the Electric Software Hub an important building block for the success of MB.OS.”