LG Energy Solutions (LGES) and Hyundai teamed up to build a battery cell manufacturing plant in the United States.

Hyundai Motor Group and LGES signed a memorandum of understanding on May 26 in Seoul, Korea, for a battery cell manufacturing facility in Bryan County, Savannah, Georgia. Each company holds a 50% stake in the joint venture for the U.S.-based battery plant. The companies plan to invest over $4.3 billion in the battery facility.

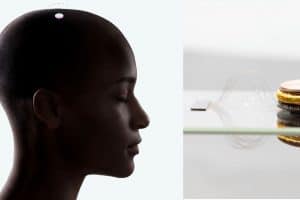

The parties agreed to produce EV batteries so Hyundai could accelerate its electrification efforts in North America. The battery plant would allow Hyundai electric vehicles (EV) to qualify for the Inflation Reduction Act’s (IRA) $7,500 tax credit.

“Hyundai Motor Group is focusing on its electrification efforts to secure a leadership position in the global auto industry. We will create a strong foundation to lead the global EV transition through establishing a new EV battery cell plant with LG Energy Solution, a leading global battery producer, and long-time partner,” said Jaehoon Chang, President and CEO of Hyundai Motor Company.

Construction on the new battery facility is expected to start in the second half of 2023, with cell production slated to begin by the end of 2025. Hyundai and LGES aim for an annual production capacity of 30 GWh at the battery facility in Georgia, enough to support the production of 300,000 EVs annually.

Hyundai Mobis will assemble battery packs using the cells from the plant in Georgia. After assembly, the battery packs will go to U.S. manufacturing facilities producing Hyundai, Kia, and Genesis EV models.

Hyundai aims to become one of the top three global automakers by 2030. The company is already preparing to achieve its goal by investing $18.1 billion in electric vehicle production. The Asian automaker plans to increase its annual production run rate for EVs to 3.64 million globally by 2030. Hyundai will launch 31 EV models from its brands, including Kia and Genesis, to reach its goal. Most of Hyundai’s EV models will be available in all major markets.