Sales of new light-duty plug-in electric vehicles, including all-electric vehicles (EVs) and plug-in hybrid electric vehicles (PHEVs), nearly doubled from 308,000 in 2020 to 608,000 in 2021. EV sales accounted for 73% of all plug-in electric vehicle sales in 2021. EV sales grew by 85% from 2020 to 2021, while sales of PHEVs more than doubled, with an increase of 138% over the previous year. The rapid growth in plug-in electric vehicle sales from 2020 to 2021 is remarkable in the context of overall light-duty vehicle sales, which increased by only 3% during the same period.

In the meantime, deliveries of internal combustion engine (ICE) vehicles were lifeless.

EV orders are so robust that manufacturers require deposits well in advance of tentative delivery dates. Our neighbor, who was able to get in on the first orders of the Cadillac Lyriq, has been waiting a year for delivery. And he’s lucky — many EV models have waiting lists of up to 2 years.

I was fortunate — my Tesla Model Y arrived just 4 months after I completed the online order form. That relatively quick turnaround seems a thing of the past, at least for now.

At last count, other Tesla models are also in high demand. The yet-to-be-released and futuristic Tesla Cybertruck has estimates of well over one million reservations.

The New York Times argues that “battery-powered cars are having a breakthrough moment.” The moment, they say, is “erasing any doubt that the internal combustion engine is lurching toward obsolescence.”

That statement is hard to contest. Electric vehicles are reshaping the auto industry.

What is more curious to me is why automakers and their subsidiaries are so slow to jump on the proverbial bandwagon. There are so many expansion and innovation opportunities! Why have legacy carmakers, original equipment manufacturers (OEMs), and replacement parts makers, among others, been so slow to join the EV revolution?

The transformation of the personal transportation sector to all-electric vehicles is definitely reshaping the auto industry. Tesla, with CEO Elon Musk at the helm, delivered nearly a million cars in 2021, a 90% increase from 2020. Wedbush, a wealth management brokerage, anticipates that the EV marketplace will change significantly over the next decade. Managing Director Dan Ives expects the electric vehicle industry to grow into a $5 trillion market by 2030, calling the transformation “a green tidal wave” that’s being propelled by “a massive headwind.”

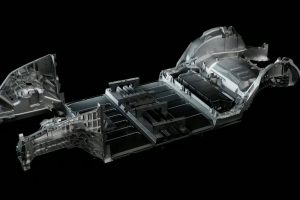

Those trillions of dollars will be spent to refit and build factories, train workers, write software, upgrade dealerships, and more. The rise of EVs means that new types of car components like electric motors, lithium batteries, chargers, and controllers are becoming the jargon of cars.

But is the move to EVs and their subsidiaries too little, too late?

Many existing auto industry companies won’t be able to join in with the EV revolution. Toyota, a pioneer in hybrid vehicles, will not offer a car powered solely by batteries until later this year. Ram does not plan to release a competitor to Ford’s Lightning until 2024. Makers of mufflers, fuel injection systems, and other parts won’t be needed soon, as EVs, in their simplicity, don’t need many elements of ICEs.

Electric Trucks: A Real Opportunity to Delve into the EV Marketplace

“Pickup trucks embody the American spirit — and for more than half of consumers, the word ‘American’ comes to mind when they think of the iconic style,” explains Jenni Newman, Cars.com editor-in-chief. Think of the opportunities for factory workers and businesses if electrification emphasis were to be placed on the favorite of all US personal vehicles: the pickup truck. Pickup trucks accounted for 14% of light-duty vehicle sales in the US in 2020, and the market share of both pickups and SUVs has grown in recent years.

ICE light-duty vehicles, including sedans, SUVs, and pickup trucks, are problematic: they are currently responsible for 58% of US transportation sector greenhouse gas emissions.

Several studies have examined the long-term effects of light-duty vehicle electrification.

Pickup trucks are only the starting place for interest in electrification of larger vehicles. The International Council on Clean Transportation offers some interesting statistics about Class 2b and 3 commercial vehicles. These include utility and delivery vans, step vans, heavy pickup trucks, and urban delivery trucks, falling in between light-duty passenger vehicles and heavy-duty commercial vehicles.

- While the current market for zero emission commercial vehicles is nascent, there has been growing interest in the deployment of electric Class 2b and 3 vehicles from both the supply and demand side.

- Several major original equipment manufacturers (OEM), alongside numerous startups, have announced plans to introduce several electric pickup truck and van models in the coming years.

- Consumer interest in the electric market for pickup trucks and vans is also clear—as of September 2021, over 130,000 preorders have been made for the Ford F-150 Lightning electric pickup truck only 5 months after its announcement in May, 2021. Initial plans to make 75,000 per year has been converted to goals twice that amount. The Lightning starts at $40,000 and runs up to more than $90,000.

- Amazon ordered 100,000 electric delivery vans from Rivian in 2019, which are intended to be in operation by 2024.

- Just 120 electric commercial trucks across all weight classes were registered in the US in 2020.

A research team comprised of members from the Georgia Institute of Technology and the State of Georgia division of the US DOT is currently conducting a case study analysis approach to assess the costs and benefits of plug-in electric vehicle (PEV) conversion for an array of commercial fleets. Their research is grounded in the premise that supporting the electrification of the light commercial fleet may be one of the most cost-effective strategies for reducing fuel use and greenhouse gas (GHG) emissions, given that these vehicles accumulate many miles each year and the extensive power demands for truck-mounted/mobile equipment for goods refrigeration and cabin comfort.

More significant health benefits may also be obtained from Class 2b and Class 3 vehicles because they are used primarily for local driving, vehicles are often kept at a central location, vehicles are driven in frequent stop-and-go and short-range duty cycles, and some vehicles idle extensively at job sites. Short range, stop-and-go, heavy-idling duty cycles can be ideal for PEVs. The Georgia researchers are concerned that fleet owners have paid limited attention to electrifying their Class 2b and Class 3 commercial fleets and that manufacturers are currently offering a limited selection of commercial PEV options.

A combined University of Michigan and Ford Motor Co. study this month described their cradle-to-grave assessment of the life cycle of pickup trucks and compared the implications of pickup truck electrification to those of sedan and SUV electrification. They found that for sedans, SUVs, and pickup trucks, battery-electric vehicles have approximately 64% lower cradle-to-grave life cycle greenhouse gas emissions than internal-combustion-engine vehicles on average across the US. Researchers found that public concerns about battery-electric vehicles having higher emissions than internal-combustion-engine vehicles or hybrids are largely unfounded, as battery-electric vehicles outperform hybrids in 95%-96% of counties, while battery-electric vehicles outperform internal-combustion-engine vehicles in 98%-99% of counties, even assuming only modest progress towards grid decarbonization.

Possibility of Leaving the US Autoworker Behind

Failure to offer enough EV models of all kinds may mean leaving many workers jobless. Nearly 3 million US workers make, sell, and service cars and auto parts, and producing EVs requires fewer workers because they have fewer components.

Too many industry analysts calculated that EVs wouldn’t become popular until they became as inexpensive to buy as gasoline models. As battery power takes market share, conventional models will benefit less from the cost savings that come from stamping out the same vehicle hundreds of thousands of times. The falling cost of producing batteries for electric vehicles, combined with dedicated production lines in carmakers’ plants, will make EVs cheaper to buy than gas-powered cars, on average, within the next 6 years. Analysts also didn’t take into account the life cost of owning an EV — there is no place in the US in which gas-powered cars are cheaper than EVs to own and operate.

Dislocation of workers seems likely, as most new battery and electric car factories planned by automakers are in Southern states like Georgia, Kentucky, North Carolina, and Tennessee. Their gains could come at the expense of the Midwest, which would lose internal combustion production jobs. The companies most endangered may be small machine shops in Michigan or Ontario that produce piston rings and other parts.

Carla Bailo, chief executive of the Center for Automotive Research in Ann Arbor, Michigan, notes that “a lot of them kind of have blinders on and are not looking that far down the road. That’s troubling.”