- 🔋 Tesla is planning in-house manufacturing of LFP batteries, as indicated by a new job listing for a Senior Cell Materials Engineer.

- 🌐 The job listing is for a position located in Palo Alto, California, at Tesla’s AI and engineering headquarters.

- 🚗 This move comes after Tesla discontinued its Model 3 RWD with LFP batteries, coinciding with new U.S. tariffs on Chinese lithium-ion batteries.

- 🏭 The potential for in-house LFP production may be connected with expansion plans at Tesla’s Gigafactory in Nevada.

- 🤝 Tesla might collaborate with Contemporary Amperex Technology Co. Limited (CATL) for low-cost batteries and machinery for in-house production.

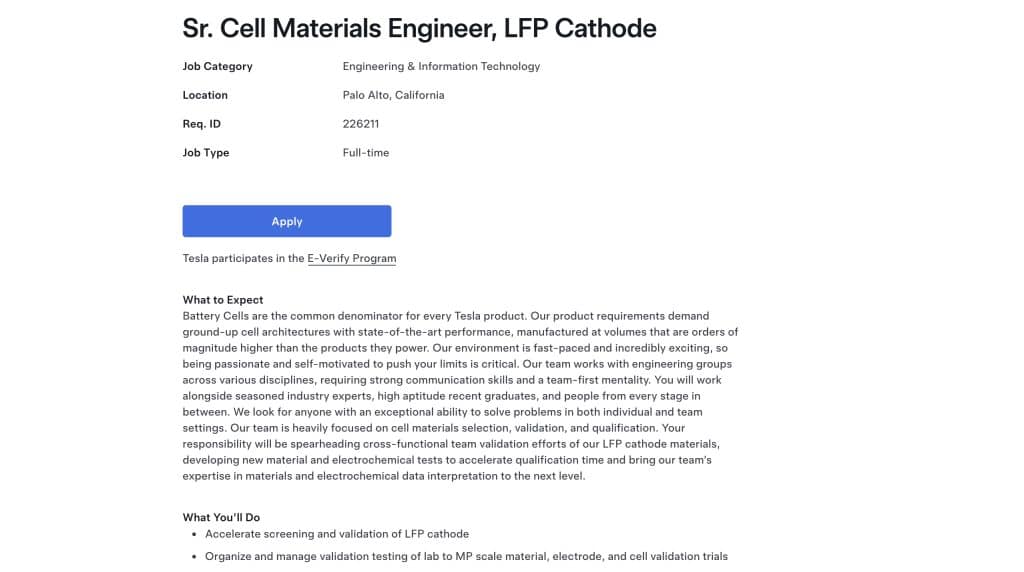

In a significant move that could reshape the landscape of electric vehicle batteries, Tesla has embarked on a new strategic initiative to manufacture lithium iron phosphate (LFP) batteries in-house. This development was unveiled through a recent job listing for a Senior Cell Materials Engineer, marking a pivotal step in Tesla’s ongoing quest for battery innovation and independence.

Why LFP Batteries Matter

The Benefits of LFP Chemistry

LFP batteries bring several advantages that align perfectly with Tesla’s vision:

- Cost Efficiency: LFP batteries are cheaper to produce due to the absence of cobalt, a costly element traditionally used in other types of lithium-ion batteries.

- Longevity: They offer a longer lifespan and enhanced stability, making them an attractive choice for electric vehicles focusing on efficiency and durability.

- Thermal Stability: LFP batteries are known for better thermal stability, reducing the risk of overheating compared to other chemical compositions.

Palo Alto: The Heart of Tesla’s Engineering Marvel

Tesla’s decision to base this new venture out of their AI and engineering headquarters in Palo Alto, California, signifies the importance of this initiative. Palo Alto serves as the hub for Tesla’s most ambitious projects and groundbreaking innovations. The new job listing for a Senior Cell Materials Engineer suggests:

- Localized Development: Bringing production closer to home can enhance quality control and faster iteration cycles.

- Cutting-Edge Innovation: Situated in Silicon Valley, the access to a pool of tech-savvy talent is unmatched, promoting rapid advancements in battery technology.

The Bigger Picture: Tariffs and Global Strategy

Tesla’s move toward in-house LFP battery production also comes against a backdrop of broader geopolitical and economic considerations. Recent U.S. tariffs on Chinese lithium-ion batteries have added a layer of complexity to Tesla’s supply chain strategy, compelling the company to seek more control over its manufacturing processes.

Implications of the New Tariffs

- Cost Pressure: The tariffs have notably increased the cost of importing batteries, pushing Tesla to explore domestic alternatives.

- Supply Chain Resilience: By producing batteries in-house, Tesla can mitigate risk associated with international supply chain disruptions.

Gigafactory Nevada and the Role of CATL

Rumors and strategic insights suggest that Tesla’s in-house production efforts could be linked with expansion plans at the Gigafactory in Nevada. The facility is poised to become a powerhouse in battery cell manufacturing with its aim to produce 100 GWh of 4680 cells.

CATL Collaboration

Contemporary Amperex Technology Co. Limited (CATL) has been identified as a potential partner. The key points of their collaboration include:

- Cost-Effective Solutions: CATL’s expertise could help Tesla streamline processes and reduce manufacturing costs.

- Technical Synergy: Through shared technological insights and machinery, both firms could accelerate innovation in LFP battery technology.

What This Means for the EV Market

Tesla’s initiative could set a precedent for the electric vehicle market in a few ways:

- Increased Adoption of LFP Technology: Tesla’s endorsement of LFP batteries might encourage other automakers to shift toward this chemistry.

- Enhanced Competitiveness: By lowering battery costs, Tesla could offer more affordable electric vehicles, expanding the market’s reach.

- Leadership in Sustainability: Using more sustainable battery components, Tesla can further its mission to accelerate the world’s transition to sustainable energy.

Conclusion

Tesla’s move to produce LFP batteries in-house marks a significant strategic shift with vast implications for the company and the broader electric vehicle industry. By focusing on local production, Tesla aims to reduce dependence on external supplies, innovate faster, and potentially transform the market with affordable and sustainable battery solutions.